Often times engineers don’t consider RoHS and Reach Compliance a criterion upfront when choosing parts for their design. Sometimes, the thought occurs AFTER they’ve sent a product to the manufacturer, only to be turned away.

Compliance Challenges

For those who don’t know what RoHs and Reach Compliance is, RoHs is short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment. This was approved in February 2003 by the European union. Reach Compliance is a general regulation, and stands for: registration, evaluation, authorization, restriction of chemicals, and addresses the production and use of chemical substances and their potential impact on human health and the environment.

A lot of engineers are receiving pressure to do more thorough checks of parts up-front knowing what the expected lifecycle is for a part-as well as knowing if it is compliant with the rules and regulations required for the markets the product will be sold in. Engineers should think of RoHS early on in their design, but what if they can’t find the information they need to make an informed decision during the selection process of a part?

Without this critical supply chain information factored in during the design phase expensive late stage design changes are often the result. If non-compliant or obsolete parts are found during procurement/manufacturing your team will have to come up with a replacement. All of this takes time and can cause project schedules to be delayed and launch timeframes to be missed.

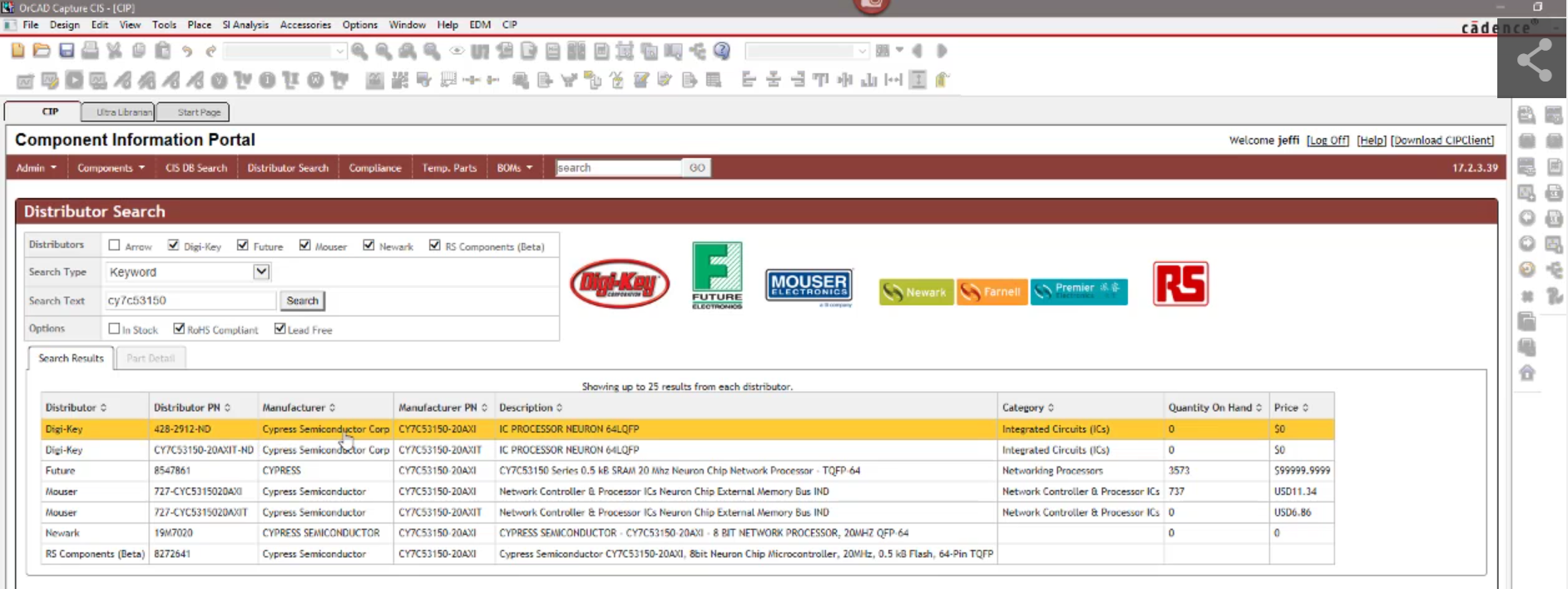

Enter the OrCAD CIP Compliance Module

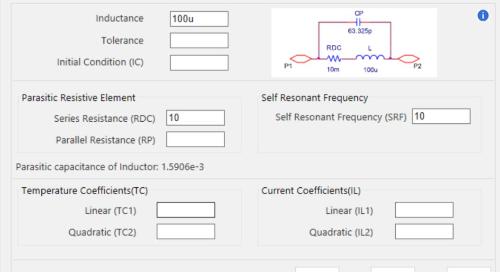

Engineers using OrCAD have long had an advantage with the OrCAD Component Information Portal (CIP) which pipes component distributor and part parametric information directly onto the OrCAD desktop. We have recently extended the information available to engineers through the new OrCAD CIP Compliance module which makes it easy to identify non-compliant and at risk components (including REACH & RoHS). Providing engineers this data upfront enables informed part selection decisions which mitigate risk and helps avoid errors and time consuming costly redesign cycles.

Save Time, Reducing Costs, and Helping the Environment

By helping engineers find the information on the parts they need, we are also helping the environment by not allowing the use of these restricted materials to pollute our landfills. These materials are also hazardous and dangerous in terms of occupational exposure during manufacturing and recycling.

Learn more about the OrCAD CIP Compliance Module.