Poor component selection can lead to many problems within our electronic design, PCB layout, schedule, etc. Luckily, there are many ways to choose parts that will deliver projects on time and produce functional boards, leaving both you and your clients happy.

The most important step in part selection is design requirements. The real problem we’re solving isn’t which parts to choose, but which parameters and functions we need to satisfy the project needs—parts just help achieve those needs.

How to select electronic components

The following guidelines will help to find and select the ideal electronic components/devices for any project.

- A clear, functional block diagram is essential

A picture is worth a thousand words; a functional block diagram is worth ten thousand. An accurate depiction of the system is essential to understand the problems we are solving and is achieved with the functional block diagram. Nothing describes an electrical problem better than a system block diagram. System block diagrams allow us to see how things are connected as well as what functions, features, and objects affect one another and why. Once we meet the needs of those function blocks, we meet the needs of the system.

- Circuits must meet required functionality

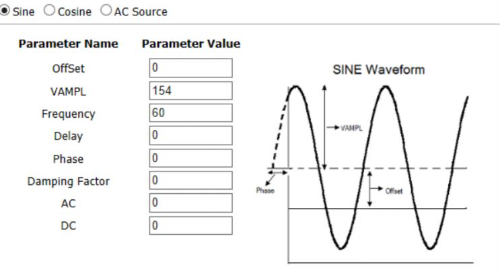

Now that we have a functional block diagram and function blocks, we dig deeper. We must create the circuit topologies that perform the functions in those function blocks.

For instance, let’s say we need a function block to change a 12 V input to a 24 V output. With our engineering knowledge and expertise, we know a boost converter is needed to perform that function.

Sometimes additional resources can be used to aid in the creation of these circuit topologies. I recommend reading application notes and reference designs for projects similar to yours. They can act as cheat sheets to find the types of circuits you need to meet a system block’s required functionality.

- Find parts that fit into the circuit topology and parameters

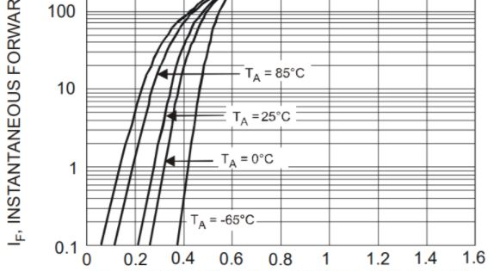

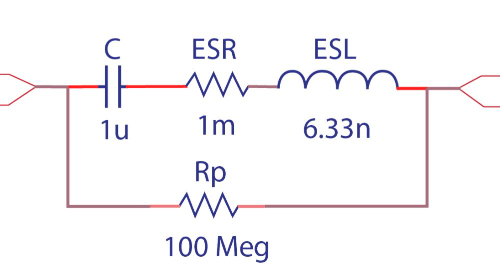

We need to find parts that meet our circuit requirements (topology, operating voltage, and current). Electronic devices are rated for specific parameters, such as voltage, current, bandwidth, temperature, etc. These part selection requirements come from the circuit topology. Once we know the types of components that will meet our topological, voltage and current needs, we need to go shopping for those components.

- Trusted Suppliers are Key

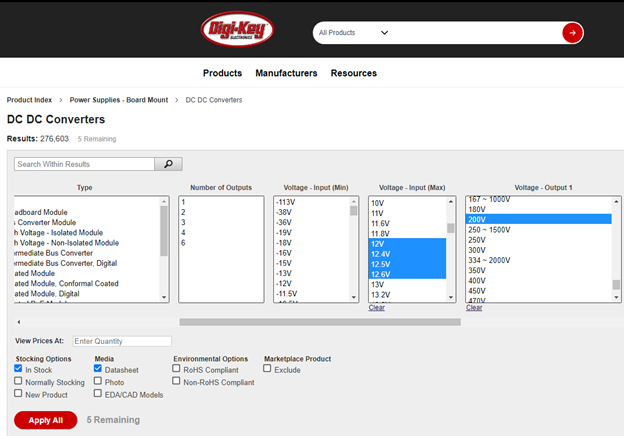

Time to market is very important for many hardware designers, so we need our parts to show up on time to meet project deadlines. To achieve this, we work with reliable part vendors. It’s even better when those vendors help us boost our efficiency in selecting and ordering those parts through a good online bill of materials tool, great customer service, and good shipping practices. Some of the best examples in the USA are Digi-Key, Mouser (in Texas), Newark, Element 14, just to name a few.

- Keep Electrical and Physical Criteria in Mind

Now that we have determined design requirements and part vendor, we need to find components. When searching, enter the electrical and physical criteria we need to get a specific function/task handle.

For example, if we need something that multiplies input voltage to give a certain output voltage, search for a boost converter. A driving factor in the part selection is voltage and current specifications. Filter the search findings on the vendor’s website for the design requirements. While this narrows down the options, there are still other criteria to consider.

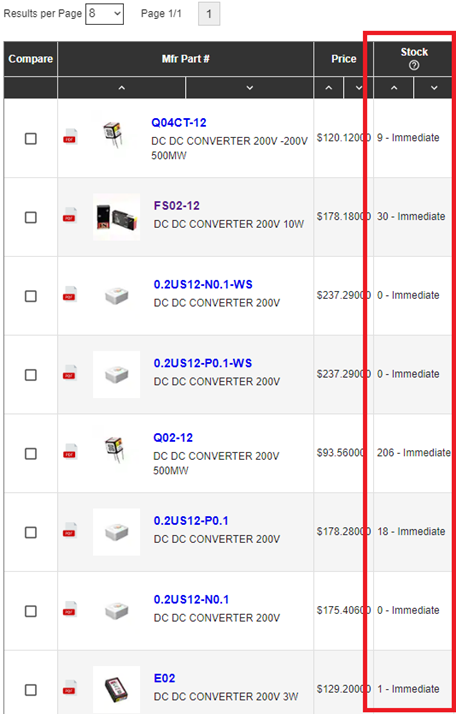

- Pay Attention to Part Availability

Lead times and unavailable parts are currently at an all-time high. Before deciding on a part, make sure it is currently available or the lead time fits within the design schedule.

I have two clients in 2021 alone who had to slow down their schedules for a couple weeks because they were waiting on parts.

- Choose Newer Parts

Whenever I work with pre-existing designs, there is at least one part that has a superior version of itself or has become obsolete. Unless a specific version of a part is needed, it's important to take advantage of newer parts that can act as direct substitutes for the older device. The newer parts tend to be more reliable, cost the same or less, are easier to find, and in stock.

- Match Parts to Meet PCB Environmental Class Requirements

Designs are typically spec’d out to work in certain temperatures, environments, and so on. Luckily, we don’t have to guess at this. PCB’s are categorized by specific classes and categories. Based on IPC standards IPC-7351B, IPC-CM-770E, and IPC-D-330, specific class ratings are given to circuit boards depending on their performance and materials.

- Class 1 – General Electronic Products that have a short life span. For example, some inexpensive toasters, small toys, and generally cheaper electronics.

- Class 2 – Dedicated-Service Electronic Products that are serviceable and repairable for a reasonable lifetime. Some examples are commercial communications devices, air conditioners, and laptops.

- Class 3 – High-Reliability Electronic Products that need to be very reliable in many different environments and have a very low failure rate. Examples of this class would be medical equipment and military weapons.

- Class 3/A – Military and/or space avionics circuits.

To meet the environmental and performance requirements of your product, it is essential to choose parts to match the class of the board (operational temperature, medical grade, etc.).

- Consider Price

The first major limiting factor in earning money is time. How long will the product take to make? The second, more important, factor is money. How much will it cost to make it? Cost is extremely important in business because it cannot survive if mass producing a product always loses money.

The cost of an electronic part goes up the harder it is to manufacture; therefore, traits such as precision of value or measurement will greatly affect part price.

- Current and Voltage range (larger range = more expensive)

- Operating Temperature (higher temperature tolerance = more expensive)

- Voltage isolation – (higher blocking voltage = more expensive)

In the end, consider the price and cost of every component in your circuit and go with the lowest priced parts that also adhere to design requirements.

- Take Minimum Order Quantity into Account

We don’t want to be purchasing 15,000 components when only 1-15 are needed. Specific component packaging (bulk, tape and reel, etc.) will have minimum order quantities associated with them. Many suppliers have different vendor part numbers based on the packaging as well. Over time, I learned that while ordering in bulk could drop part prices to fractions of a penny, most individual projects or one-off products need a minimum one-off quantity of 1, not 15,000.

Pro tip: Price per part usually decreases as you order parts in multiples of 10. Sometimes it’s more cost-effective to order 10 capacitors instead of 8. Weird, I know.

Methodology is Key

The company, client, or customer only benefits from a working product. Having a strong methodology to properly select parts is key, as one small mistake can cause a product to not work, resulting in missed product release deadlines, extended delivery schedules, more money, and frustrated customers. Selecting electronic components can be confusing and intimidating if you have never selected them on your own before. Every single component we choose will either make or break the product. Even if you choose the right components, things like budget and schedules are greatly affected by whether those parts are cost-effective and available when we need them, affecting the bottom line.

The electronic component selection guidelines above are not fully exhaustive, but will help keep your budgets and product delivery on schedule, build products that work, and satisfy your customers and clients. Then, be sure to capture your schematic properly to convey the original intent of the block diagram.