When designing PCBs today, it is important to consider where and how the board will be implemented. This inclusion of mechanical concerns during electronic circuit board design can save time and expense for product development. The quality and efficiency of your ECAD/MCAD depends on the 3D product design software capabilities of your EDA tools.

Essential 3D Product Design Software Capabilities

The engineers and designers who create the circuit boards at the heart of all electronic and electromechanical product development are constantly challenged to improve functionality and performance. Meeting these demands is not enough. Other concerns like shrinking mechanical housing put restrictions on the PCB size, thickness, and design. Successfully addressing these PCB design process issues raises the bar for PCBA design to a level beyond the capabilities of most EDA packages. The best solution is the use of product design and development software.

A specific area most design packages lack is the necessary robustness in 3D product design. Needed capabilities that, if included or added to your EDA tool capabilities, will result in successful and efficient PCBA design include the following:

3D Product Design Software Capability Needs

- 3D DRC Checking

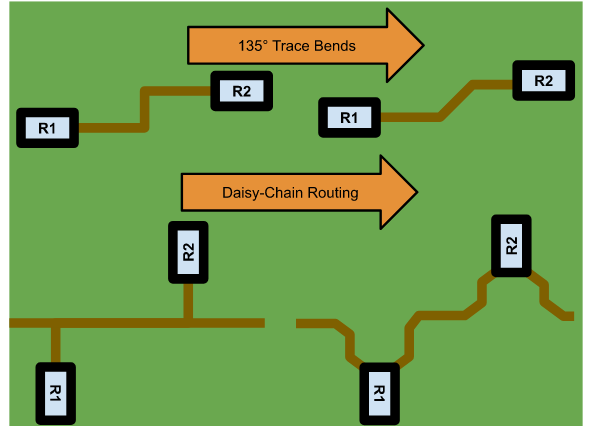

PCB layout constraints are not limited to 2D, but most EDA tool validation tools are. 3D DRC checking allows you to set rules and verify adherence for wire-to-wire spacing, metal overlaps, and other non-coplanar concerns.

- 3D Package Design

The ability to design with IC(s) and board packaging concerns incorporated is non-existent with most EDA tools. This capability shaves time from your development schedule and helps reduce costs.

- 3D EM Modeling and Simulation

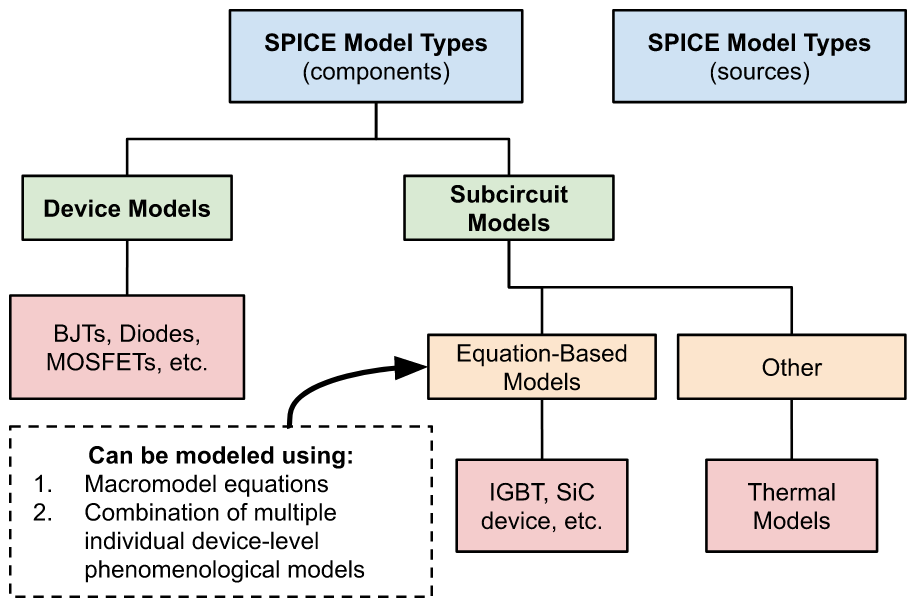

To understand the full impact of EM radiation on your board and in its operational environment, the ability to simulate and analyze 3D EM models is required.

- MCAD Aware ECAD

Instead of the slow back and forth of traditional ECAD and MCAD, MCAD Aware ECAD allows for a more collaborative, seamless design process, including design and 3D rendering of cases and enclosures in the ECAD space for visualization of the complete assembly, bending analysis for flex and rigid-flex designs, and 3D collision detection.

The above 3D product design and development software capabilities enhance your ability to innovate quickly, meet development schedules and improve efficiency.

Software Tools for 3D ECAD/MCAD Product Design

While some of these vital ECAD/MCAD design capabilities can be included with various PCB design packages, functionality can be enhanced by incorporating additional 3D product development software tools, as listed below.

3D Product Design Software Resources

- Advanced Package Design

IC, package and board optimization with true multi-fabric design capability.

- CADSync

EM Co-design compatible with- OrCAD

- Allegro PCB

- SolidWorks

- Sigrity

Perform full 3D EM analysis on imported models.

To fully leverage the capabilities these tools provide, you should rely upon an industry leader with the experience and expertise to provide the software, training, and support needed to enable you to start developing quickly.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, and engineering expertise, which enable you to create more efficiently. For more information on 3D product design software and how we can help you or your team innovate faster, contact us.